Customer Experience Center

Para conseguir una superficie de la calidad deseada en piezas complejas de fabricación aditiva, es fundamental poseer conocimientos avanzados de posprocesado. AM Solutions - 3D post processing technology, como marca del Grupo Rösler, aprovecha sus años de experiencia en soluciones orientadas a los procesos para el tratamiento de superficies.

En nuestro Centro de Experiencia del Cliente (CEC) internacional, podemos reproducir y probar de forma realista cualquier necesidad que los clientes puedan tener para el postprocesado de piezas y componentes AM. Nuestros expertos trabajan en estrecha colaboración con nuestro departamento de diseño y desarrollo para ofrecerle la solución de tratamiento ideal para sus aplicaciones concretas.

Para poder comprender las necesidades específicas de nuestros clientes, así como las particularidades del proceso de impresión 3D, contamos con diversas tecnologías de impresión y soluciones de posprocesado en nuestro CEC central de 400 m2, situado en la población alemana de Untermerzbach.

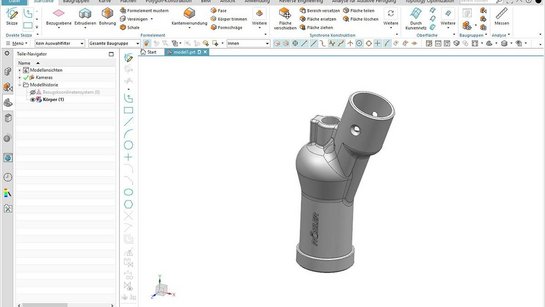

Software para CAD, Siemens NX de Siemens

NX es un reputado software CAD/CAM/CAE que proporciona todas las funcionalidades necesarias para crear y producir diseños para la fabricación aditiva a escala industrial. NX utiliza tecnologías innovadoras como el modelado convergente, la optimización de la topología y los procesadores de construcción integrados para facilitar el diseño, la simulación y la producción de piezas de fabricación aditiva.

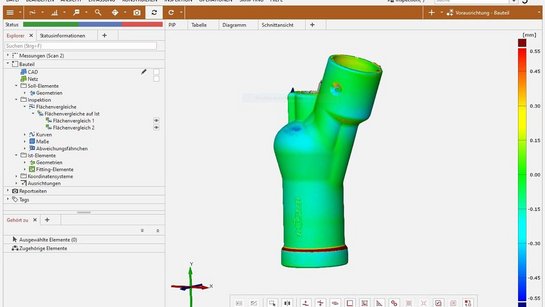

Escáner 3D, ATOS de GOM

El escáner 3D es una herramienta de digitalización óptica de alta resolución que proporciona rápidamente datos de medición tridimensionales precisos para la optimización de los procesos de ingeniería. Esto ayuda no sólo a mejorar las actividades de ingeniería inversa como preparación para la fabricación aditiva, sino también a la optimización de operaciones completas de fabricación industrial.

Impresora 3D M 290 de EOS para imprimir componentes metálicos

La EOS M290 es una impresora SLM (fusión selectiva por láser) basada en lecho de polvo para crear componentes metálicos. Con un espacio de trabajo de 250 x 250 x 325 mm (incluida la placa de impresión), la M290 está equipada con un láser de 400 vatios (lente F-Theta). Esta impresora permite la producción rápida, flexible y rentable de componentes con características estructurales homogéneas a partir de polvos metálicos.

Impresora 3D de polímeros P3 Next de EOS

La P3 NEXT de EOS se basa en la tecnología de sinterización selectiva por láser (SLS). Está equipada con un láser de CO₂ (1 × 70 W) y ofrece un volumen de construcción utilizable de 340 × 340 × 600 mm (incluida la plataforma de construcción).

Con la EOS P3 NEXT, disponemos de una plataforma que garantiza calidad, reproducibilidad y aptitud para la producción en la fabricación en serie industrial de plásticos, complementando así de manera coherente nuestra experiencia en fabricación aditiva del ámbito metálico.

Impresora PolyJet Objet260 Connex 3 de Stratasys

Gracias a la tecnología multimaterial, que es el único proceso de impresión 3D del mundo que permite procesar, combinar y mezclar simultáneamente hasta tres materiales base diferentes, se pueden producir modelos multicomponente con, por ejemplo, componentes similares al caucho, sólidos y transparentes en una sola impresión.

Impresora Multi Jet Fusion HP Jet Fusion 3D 5200

Con esta impresora, se pueden producir en un solo día prototipos funcionales de nailon y piezas de serie con una alta calidad superficial y detalles precisos. Las piezas acabadas presentan una mayor uniformidad de las propiedades mecánicas en comparación con procesos similares, como el sinterizado selectivo por láser (SLS).

S1 Wet

S2

D1

F1

M4 Basic

M1

M4

C1

DLyte 100PRO